Advantages

- Reliable process performance

- Process not affected by paper machine speed or basis weight

- Symmetrical turn-up reduces spool loss

- Minimized parent roll loose / flying paper

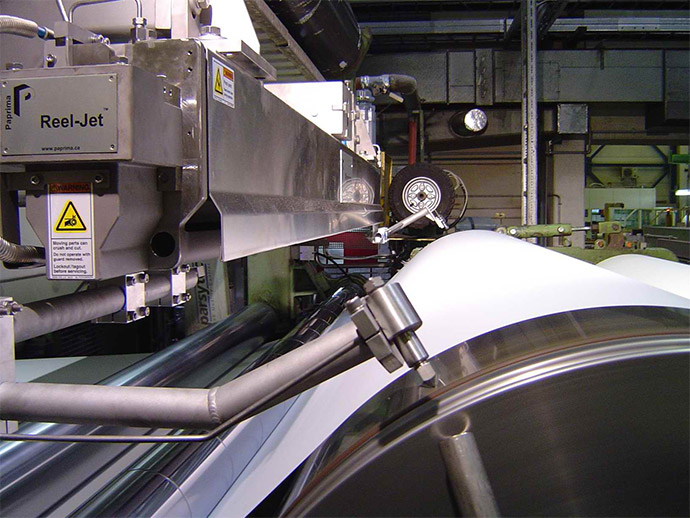

Features

- Stainless steel cross-machine beam with timing belts and tracks for carriages

- Powerful servo motor for high-speed and accurate position control

- Hose guiding and tensioning system for extended lifespan

- Use of water-soluble and fully repulpable sealant that does not leave glue or paper residue on the spool

The Reel-Jettm system provides the highest turn up efficiency in the market and significantly reduces spool loss.

The Reel-Jettm water jet turn up system can operate jointly with conventional air goosenecks, tape turn ups, and air assisted on level rail turn up systems, making the Reel-Jettm the most flexible water jet multi mode turn ups.

There are various possible turn up methods with the Reel-Jettm system.

Common methods

- Cross cutting, chevron tip creation (cutting nozzles cross one another)

- On level rail turn-up

- Pulper turn-up (following a sheet break)

- Parallel cutting for light hygiene grades (no cross of cutting nozzles)

- Parallel cutting for heavier publication/board grades (no cross of cutting nozzles), with possible auxiliary water-jet slasher

- Patented X-Cut profile to eliminate flying paper on parent roll